Premium quality

Discover the properties of our FFKM seals

FFKM joints are the solution when FKM has shown its limitations.

FFKM O-ring seal, or perfluoroelastomer, is a rubber that contains more fluorine (72.50%) than standard FKM (66%), enabling it to reach higher temperatures and greatly improving its resistance to aggressive fluids.

Special applications

Aerospace

FFKM perfluorinated O-rings are widely used in the aerospace industry for their resistance to the most extreme conditions, such as high pressure, ignition circuits and high resistance to degradation.

Chemical processing

FFKM is used in the manufacture of O-ring seals, suitable for high-temperature environments or those exposed to aggressive chemicals used in the oil industry.

Food and beverages

ULTIMA® materials offer proven high sealing performance and are suitable for CIP and SIP processes used in the food industry.

Oil and gas

FFKM seals are the best choice for withstanding high pressures and temperatures, while offering excellent resistance to corrosion caused by chemical reagents.

Medicines

FFKM, renowned for its exceptional chemical stability, heat resistance and anti-aging properties, is establishing itself as a key material in the medical field. It is able to withstand a wide range of chemical substances, and offers excellent tolerance to the strong acids, bases and organic solvents commonly encountered in medical environments.

Semiconductors O-Rings

In semiconductor applications, FFKM O-rings provide protection against contamination, while offering excellent chemical resistance and thermal stability. Thanks to their anti-expansion and anti-fragility properties, they are also ideally suited to the chemical processes used in advanced electronics.

ULTIMA industrial sealing quality at your service

Our expertise makes the difference

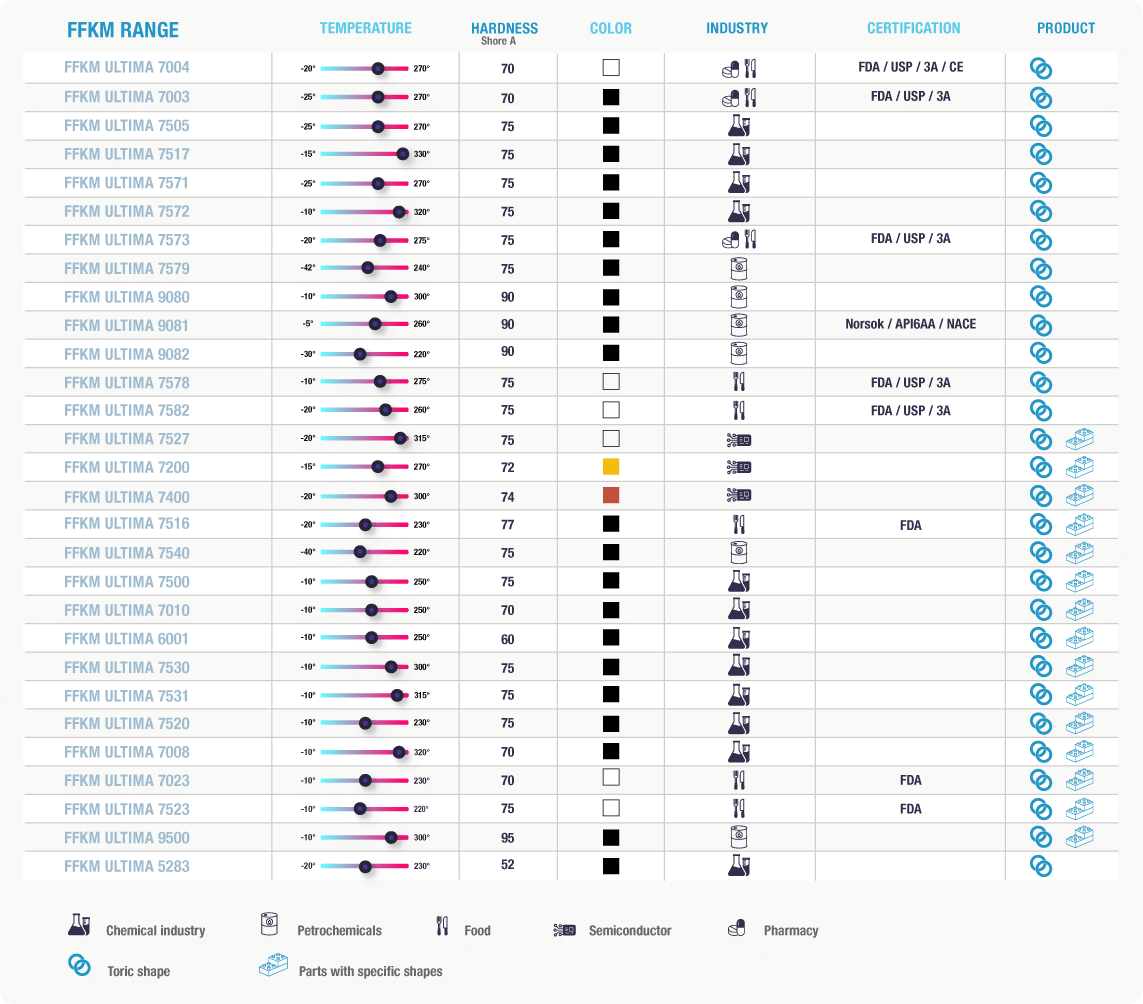

ULTIMA has been marketing its FFKM Ultima range of high-performance elastomers since 2004 in a wide variety of markets in France and Europe.

Our Ultima FFKM range is 100% Italian. To maximize synergies between the teams, the various production sites are located within a 100 km radius of Milan.

– The Research & Development division and the rubber base production site

from SOLVAY in Spinetta Marengo, Italy.

– Blending and compound production are carried out in the region of

Bergamo region

– All material storage, production and seal inspection activities are carried out at our

are carried out by our long-standing partner in the Bergamo area.

These close-knit production sites and our Italian presence enable us to

allow us :

– Constant quality control

– A limited carbon footprint for the supply of your FFKM molded parts

– Up-to-date compliance with the latest REACH and RoHS regulations.

– Reduced customs charges for our export customers in several countries

compared with products manufactured in the USA, for example.

ASTM designation: FFKM

ISO/DIN designation: FFPM

Trade names: Kalrez, Isolast, Chemraz, Parofluor

Would you like an online quote?

We’ll get back to you within 24 hours, and we also have a large stock of O-rings available for sale within 1 week.

24-hour online quote

Our stock of raw materials enables us to launch production quickly, with lead times of between 4 and 8 weeks, depending on the grade.

We also have a large stock of O-rings available for sale within 1 week.

On request, we offer supply contracts establishing a safety stock available within 24 hours, based on your consumption history.